Standard Approaches vs Fuel Vaporizers

|

Standard Efficiency ImprovementsMost attempts by the vehicle manufacturers to increase fuel efficiency are centered around two approaches: reduction in weight, and refinement in engine design and fuel delivery systems. The reduction in weight has reached an effective plateau, as long as conventional metals are used in construction. Engine design has also reached somewhat a plateau, although there always seems to be continual tweaking and development which leads to marginal gains in performance and/or economy. Fuel delivery systems become more and more micro-processor controlled, but again, this can reach a plateau as long as conventional delivery of fuel is maintained, although finely controlled.

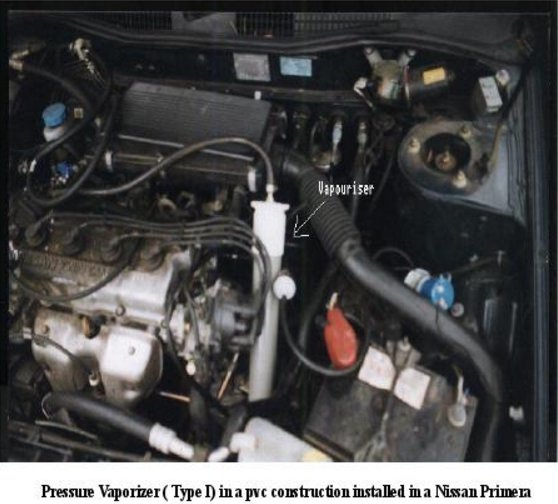

An Alternative - the Fuel VaporizerOne area of improvement which has almost entirely been overlooked by the motoring companies is in the treatment of the fuel before being burned, i.e., vaporisation. By vaporising the fuel before it enters the combustion chamber, we can neatly circumvent the problem of not having enough time to thoroughly vaporise it after it has entered the combustion chamber. Remember, only vaporised fuel will burn. By doing this, we can effect substantial savings in fuel economy and pollution reduction. We offer two vaporizer versions, and also information on how to build your own. The core concepts of the devices come from George Wiseman of British Columbia, Canada. He publishes information on some devices and some parts, but he has not patented the information, purposely. I have taken these concepts and done further experimentation and development, and have come up with my own versions, again, which are not patented. The principles are the same between Eagle Research and ours, but the design and operation differs significantly on a number of points. |